China 6 Axis 1800mm Arm ifika pa Automatic Steel MIG Welding Robotic Arm

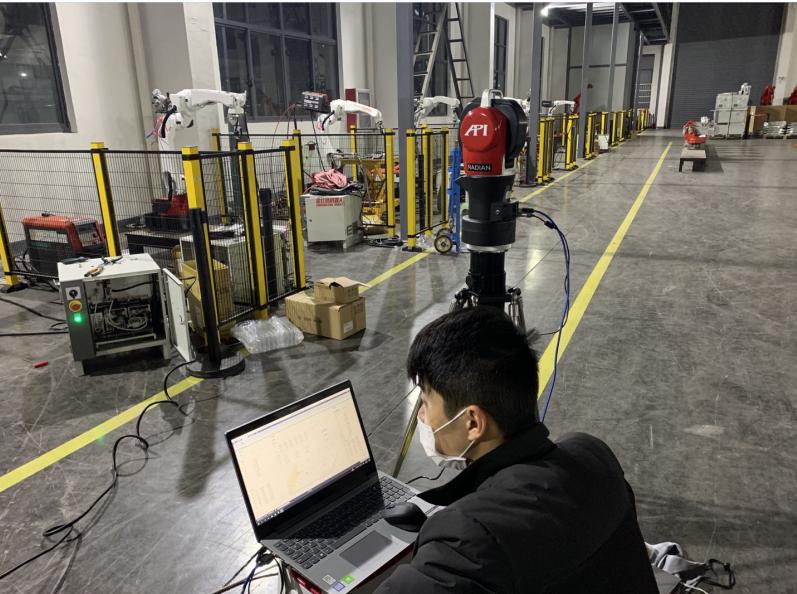

LASER CALIBRATION TEST REPOSITIONING KUSINTHA

JHY amagwiritsa ntchito njira ya laser calibration kuyesa kulondola kobwerezabwereza kwa loboti.Pambuyo pa mayeso ambiri, kulondola kobwerezabwereza kwa loboti yathu ndikokwera kwambiri kuposa ± 0.08mm.

GWIRITSANI NTCHITO ZOPHUNZITSIRA ZOKHUDZA ZOTHANDIZA

Zida zazikulu za robot monga servo motor, RV reducer, harmonic reducer, servo drive ndi zina zotero zimagwiritsa ntchito mitundu yapamwamba ya China, yomwe yayesedwa ndikugwiritsa ntchito nthawi yaitali kuti tiwonetsetse kuti ndi yoyenera kwa robot yathu.

KUCHULUKA KWAMBIRI

Kukonza n'kosavuta, Malinga ndi kalozera yokonza zoperekedwa ndi ife makasitomala okha mosavuta ntchito.

ATAGULITSA GUARANTEE

Makasitomala aliyense ali ndi gulu lake lantchito pambuyo pa malonda.Ngati mukufuna thandizo lililonse pambuyo pogulitsa, Pls funsani nthawi iliyonse.Akatswiri athu akatswiri adzathetsa mu nthawi yochepa.Mfundo ndi yakuti zonse ndi zaulere.

| Zowotcherera magawo za zitsulo zofatsa ndi chitsulo chochepa cha alloy | |||||||||

| mtundu | mbale | Waya awiri | kusiyana kwa mizu | kuwotcherera panopa | kuwotcherera mphamvu | liwiro kuwotcherera | Lumikizanani nsonga-workpiece mtunda | Kutuluka kwa gasi | Welding angle |

| kuwotcherera matako ooneka ngati T | 1.0 | 0.8 | 2.5-3 | 70-80 | 17; 18 | 8; 10 | 10 | 10-15 | 45° |

| 1.2 | 1.0 | 3 - 3.5 | 85; 90 | 18; 19 | 8; 10 | 10 | 10-15 | 45° | |

| 1.6 | 1.0,1.2 | 3 - 3.5 | 100-110 | 18-19.5 | 8; 10 | 10 | 10-15 | 45° | |

| 2.0 | 1.0,1.2 | 3 - 3.5 | 115-125 | 19.5-20 | 8; 10 | 10 | 10-15 | 45° | |

| 2.3 | 1.0,1.2 | 3 - 3.5 | 130-140 | 19.5-21 | 8; 10 | 10 | 10-15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5-4 | 150-170 | 21-22 | 7.5-8 | 15 | 15-20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5 ~ 5 | 180-220 | 21; 23 | 6.5-7.5 | 15 | 15-20 | 45° | |

| 1.2 | 5 - 5.5 | 200-250 | 24; 26 | 6.5-8 | 10-15 | 10-20 | 45° | ||

| 6 | 1.2 | 5 - 5.5 | 230-260 | 25; 27 | 6.5-7.5 | 20 | 15-20 | 45° | |

| 6 | 220-250 | 25; 27 | 5.5-7.5 | 13-18 | 10-20 | 45° | |||

| 4; 4.5 | 270-300 | 28-31 | 10-11.5 | 13-18 | 10-20 | 45° | |||

| 8, 9 | 1.2,1.6 | 6; 7 | 270-380 | 29; 35 | 6.5-7.5 | 25 | 20-25 | 50° | |

| 8 | 1.2 | 5; 6 | 270-300 | 28-31 | 9;10 | 13-18 | 10-20 | 45° | |

| 1.2 | 7; 8 | 260-300 | 26-32 | 4 ndi 5.5 | 15-20 | 10-20 | 50° | ||

| 1.6 | 6.5-7 | 300-330 | 30; 34 | 5 - 5.5 | 15-20 | 10-20 | 50° | ||

| 12 | 1.2,1.6 | 7; 8 | 270-380 | 27; 35 | 4.5-6.5 | 20-25 | 20-25 | 50° | |

| 1.2 | 7; 8 | 260-300 | 26-32 | 4 ndi 5.5 | 15-20 | 10-20 | 50° | ||

| 1.6 | 6.5-7 | 300-330 | 30; 34 | 5; 6 | 15-20 | 10-20 | 50° | ||

Zindikirani:

1. Kuwotcherera kwa MIG kumagwiritsa ntchito mpweya wa inert, womwe umagwiritsidwa ntchito kwambiri powotcherera aluminiyamu ndi ma aloyi ake, mkuwa ndi ma aloyi ake, titaniyamu ndi ma aloyi ake, komanso chitsulo chosapanga dzimbiri ndi chitsulo chosagwira kutentha.kuwotcherera kwa MAG ndi CO2 zotetezedwa ndi gasi zimagwiritsidwa ntchito kwambiri pakuwotcherera chitsulo cha kaboni ndi chitsulo chochepa champhamvu kwambiri.

2. Zomwe zili pamwambazi ndizomwe zimangogwiritsidwa ntchito, ndipo ndi bwino kupeza njira zoyenera zowotcherera pogwiritsa ntchito kutsimikizira koyesera.Ma diameter a waya omwe ali pamwambawa amatengera zitsanzo zenizeni.